Tiles Material Used And Grading

tiles material in order to gain their certain grading must pass a complicated process and have been compressed and burned repeatedly at high temperatures

They become exceedingly powerful and thick as a result

Additionally, it enables the creation of gigantic sizes

The product is durable, making it less prone to chip, and the color penetrates the whole thickness of the tile

Ceramic, Clay, sand, and water are compacted together to eliminate the extra moisture to create ceramic tile, a material that has been used for hundreds of years

They are also highly tough and long-lasting, although they aren’t quite as impermeable as their porcelain relatives

You’ll also notice a chip more readily than you would in a porcelain tile since the color doesn’t penetrate all the way through a ceramic tile

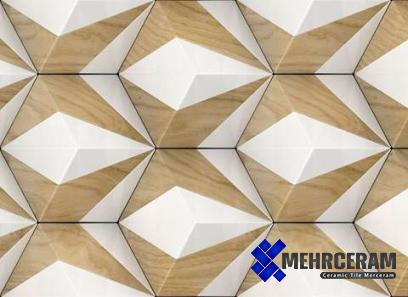

Glass, Glass tiles are available in a wide range of eye-catching hues and types

Expect installation labor to be somewhat more expensive since they need to be installed properly by a trained specialist

This tile is not for do-it-yourselfers

You should pay attention to the mortars and grouts being used to install them since it is also not very scratch resistant

Stone, Stone tiles such as marble, granite, travertine, and slate are extracted from the soil and are only limited by mother nature’s ability to create stunning hues and designs

Stones are very distinctive ornaments for your house since no two are similar

The majority are quite porous and need sealers to prevent stains

Some, like marble, are relatively soft, and wear and cracking may be issued in locations with heavy activity

due to its greater maintenance requirements

The majority are quite porous and need sealers to prevent stains

Some, like marble, are relatively soft, and wear and cracking may be issued in locations with a lot of traffic

Ceramic Tiles Grades

The PEI, rating of ceramic tile’s grades durability is used to determine this for everyone else around the globe

The PEI scale ranges from I to V (1 to 5 ), with V being the most robust

The majority of tile producers use this scale, which needs to be written someplace on the tile box, to assess the durability of the surface wear

If it isn’t, you may always get the details by getting in touch with your tile maker

The following are general recommendations for appropriate installation areas: Group I: Tile that should only be used for inside walls in homes or businesses; unless you’re Spider-Man, you shouldn’t walk on this material

Not appropriate or advised for foot traffic (unless you are, indeed, Spiderman)

Group II tiles: These are acceptable for mild domestic traffic in general

Not suggested for use in kitchens, foyers, frequently used bathroom floors, or any other location with constant foot activity

Group III tiling is appropriate for all residential and lightly trafficked commercial locations

Except for your garage floor, you can fairly much place this wherever in your home

Group IV: Tile is suitable for all residential, medium commercial, and light industrial uses, such as lobbies of hotels, restaurants, and medical facilities

The Space Shuttle, malls, airports, and other large commercial and industrial uses are all suited for Group V tiles

Only the tile surface’s durability is measured by the specific group number or PEI grade

Only the quality and longevity of the surface or glaze are determined, not the slip resistance, general strength, moisture absorption, or quality of the tile itself

A PEI rating of three or above is usually recommended for most residential flooring applications, however, a two is acceptable in certain cases

Difference Between A Grade And B Grade Tiles

The first and obvious difference between a grade and b grade tile is referred to as quality but besides it, other factors can be caused, no manufacturer will purposefully make Grade B tiles (2nd Grade Tile)

The primary goal of the factory is to produce Grade A (1st Grade) tiles, alternatively, to attain a production yield of 100% of that

However, in practice, this is not feasible

Manufacturing mistakes may occur, and the yield of Grade A tiles, which is regarded as impressive production output, may vary from 94 to 97 percent

The remaining 3 to 6 percent of the production is either rejected or degraded to be marketed as Grade B tiles

In the market, Grade A tile commands a much larger premium than Grade B tile

Tiles, like other burned goods, are liable to have tolerances owing to production-related shrinkages, and may be graded in accordance with a set of international standards, in this instance Malaysian Standard MS ISO 13006

Let’s now go further into the subjects or standards that distinguish Grade A tiles from Grade B tiles based on what we can tell from their outward looks

It is obvious that grade two tiles perform similarly to grade one tiles when used for walls and backsplashes

They may, however, also be used as flooring in places with little foot activity

Although grade two tiles are a less expensive alternative for bathroom floors, they are not advised for rooms with more usage, such as kitchens or living rooms

ceramics’ quality Class B: It is in the range of Grades A

It can tolerate and grade b is not so suggested for high traffic places such as kitchens or walkways but totally it has an acceptable quality

Floor Tiles Classification

floor tiles are divided into several classifications based on how they are made—dry pressing or extrusion—and how well they absorb water

Following the categorization, AS 4459 Techniques of sampling and analysis of ceramic tiles identify the mechanical/chemical qualities needed

Rating systems for floor tiles will assist you in selecting the best option

The following information will help you comprehend what a floor tile evaluation process is all about

The most resilient flooring solutions are made of porcelain and ceramic tiles

They work well in kitchens, baths, and the majority of living spaces in your house

Ceramic and porcelain tiles are the two primary kinds

Ceramic tiles come in the whole body and glazed varieties

Although porcelain costs a bit more, it is more resilient and less prone to crack or scratch

Ceramic tiles are less costly than porcelain tiles on average, however, they are less long-lasting

Tile Classifications under the Floor Tile Rating System

Tiles that absorb water at less than 0

5 percent are considered impervious

Porcelain tiles that absorb more than 0

5 percent of water but not more than 3 percent are considered vitreous (or high-density) tiles

Semi-vitreous tiles—also known as semi-vitrified or medium-density tiles—absorb more than 3% but not more than 7% of water

tiles made of non-vitreous materials that absorb water at a rate of more than 7%

What Defines The Various Ratings? The suitability of a tile for installation in a certain region is determined by its rating

The PEI rating, shade variation (v) rating, and slip rating are these ratings

PEI Rating for Hardness and Durability

On glazed porcelain and ceramic tiles, an abrasion test called a PEI rating is conducted

The degree of friction, scratches, and markings that the glazed surface can tolerate are all referred to as abrasion

Grade 1 Porcelain Tile For Floor

Grade 1 porcelain tiles for floor application have many advantages that are more susceptible to scratch than other grades

To preserve their life, frequent maintenance should be performed

However, grade one tiles are frequently the least expensive and are ideal for creating stunning backsplashes and walls

Grade 1 porcelain tile, the least resilient variety, should only be used on walls

It is not advised for countertops or flooring

Ceramic tile is exclusively advised for indoor residential and business wall installations in Class 1 (No Foot Traffic)

Additionally, class 1 tile is sometimes utilized for bathroom flooring

Ceramic tile for residential floor, countertop, and wall applications

Class 3: Light to Moderate Traffic the most typical tile used in homes They should not be used for tile flooring in commercial areas as they are not made to withstand high foot traffic

This contemporary tile is perfect for use as wall coverings as well

Grade 1: This is the least durable kind of ceramic tile available

Really, it’s only useful as a wall tile

Although it can withstand more abuse from light commercial foot traffic, such as that found in a doctor’s office, it is still a good option for residential purposes, such as tile floors and countertops

Grade 3 Ceramic Tile

It’s not surprising that ceramic grade three tiles are the most often utilized for a variety of home projects as they are the mid-level alternative

Grade 3 ceramic tile makes excellent kitchen counters or flooring, as you’ll discover and they give a charming appearance to it

Grade three tiles will confidently resist your regular wear and tear

The majority of tiles marketed as residential floor tiles are Grade 3

and also, the feature of durability makes Grade 3 ceramic tiles the most affordable among all grades therefore they are cost-effective and can work for many years in another hand grade 3 ceramic tiles are suitable for light commercial applications like offices or small stores since they can withstand normal wear and tear as well as modest foot traffic

For worktops as well as domestic usage in kitchens, living rooms, and hallways, grade 3 tiles are excellent

Porcelain tiles for outdoor usage are also an option because they are very strong and can endure rainfall and sunshine exposure

How To Check Quality Of Porcelain Tile

Checking the quality of porcelain tile is a complicated process porcelain tiles, are made by grinding, combining, pressing, glazing, and sintering resistant metal oxides and semi-metal oxides

They are acid- and alkali-resistant ceramic/stone for construction or ornamental elements

Most of its basic elements are combined with clay, quartz sand, and other minerals

Ceramic tiles may also be separated into mosaics, polished tiles, vitrified tiles, through-body tiles, etc

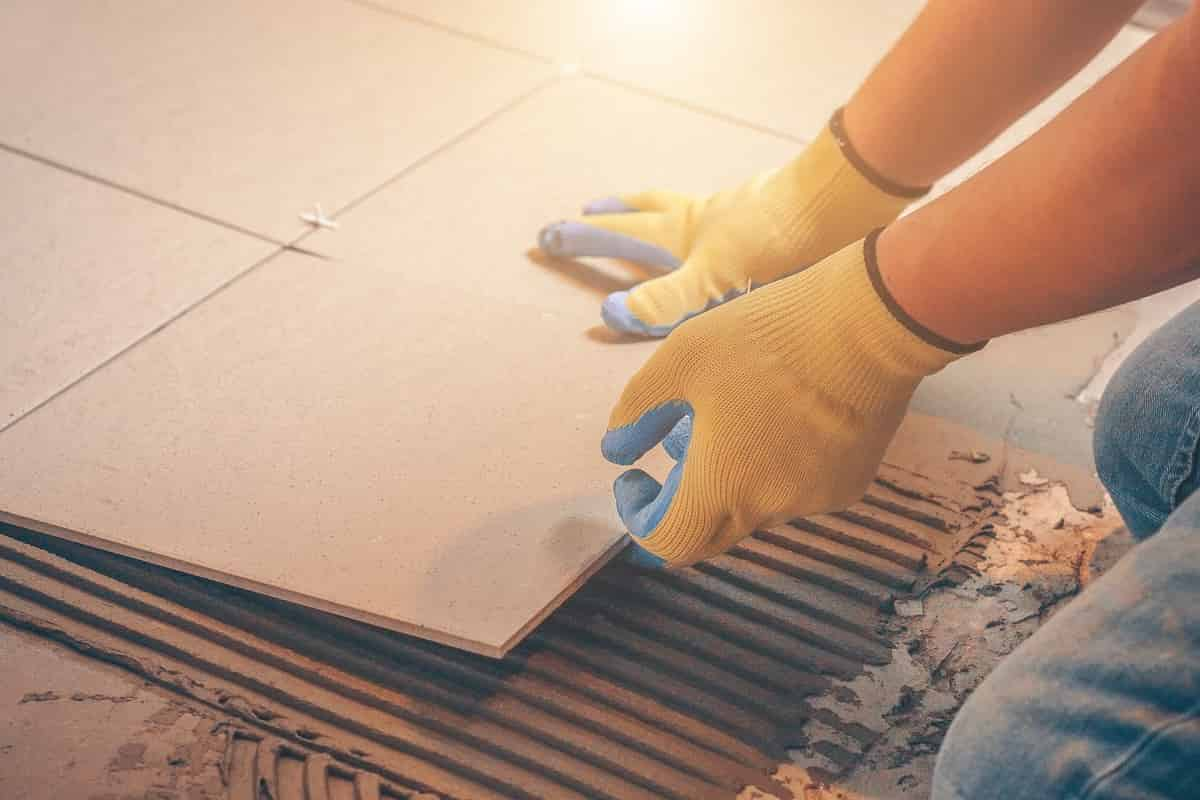

Method of identification; Take a look at how much water ceramic tiles can absorb first

The quality of ceramic tiles improves with lesser water absorption

How do you look? Pour some water on the ceramic tiles back to reveal the water drop’s region of diffusion

A tiny diffusion area indicates a low level of water absorption

Then examine the label to see whether the bottom of the tile has a typical manufacturer’s product label

It is advised to pick carefully if the label is ambiguous or absent

At the same time, look for flaws like leaks, wear and tear, and cracked, chipped, or deformed glass tiles, as well as black spots, bubbles, pinholes, cracks, scratches, stains, edges, and corners on the surface of ceramic tiles

After checking, feel the tile to see if there are any of the issues described above

When a tile feels weighty, it is of great quality and has a high density

It is lighter and of lower quality, on the other hand