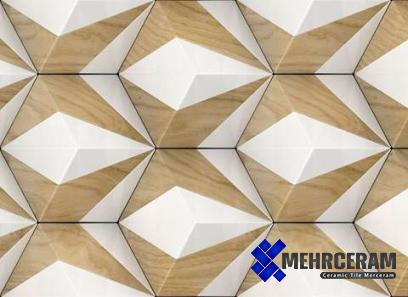

Double Charge Vitrified Glazed Tiles Price with intricate patterns

Vitrified glazed tiles are one of the newest products in the field of tiles_ whether double charge or not_ and have their distinct price range

Glazed ceramic tile is another name for tile that has been given a glaze after it has been applied

The quantity of water that they are able to take in may be used to distinguish between the many types of them

Tile

Vitrified glazed tiles often absorb less than half of one percent of water, while digital ceramic tiles typically absorb between two and five percent of the water that they come in contact with

High-volume inkjet printers and digital manufacturing technologies are used during the production of glazed tiles

Glazed tiles are the category that it is classified as belonging

Ceramic floor tiles, digital wall tiles, vitrified tiles, glazed vitrified tiles, double charged tiles, nano polished tiles, big porcelain slabs, vitrified tiles, and mosaic tiles are some of the many shapes that tiles may take

In recent years, there has been a rise in interest in the use of digital wall tiles

Glazed Vitrified Tiles Vs Double Charge

Double charge tiles vs glazed vitrified tiles have some differences

Tiles that are double charged and have two layers of ceramic tile, the top of which is crushed by a hydraulic press machine that pushes the texture with double layer pigment

These tiles are known as double charged glazed tiles

How to use broken tiles for flooring

The thickness of double charged glazed tiles is between 3 and 4 millimeters, which is much more than that of standard tiles

The manufacturing process for double-charged glazed tiles not only enables the printing of intricate patterns and textures but also produces tile surfaces that are very resistant to wear and tear, making them ideal for use in areas that receive a lot of foot traffic

This makes them an excellent choice for use in locations where there is a lot of foot traffic

A glossy and smooth coating or coatings are referred to as having a glaze when they are described using this phrase

As a direct result of this, the tiles known as glazed tiles are those that have a surface or finish that is shiny and smooth

After the glaze has been applied, the tiles are placed in an oven and cooked for a period of time

It provides a wide variety of possibilities for surfaces, such as polished tiles, high-gloss tiles, matte tiles, and non-slip surface options, so customers can pick the one that best suits their needs

Porcelain glazed wall and floor tiles

They may also be purchased in enticing patterns, from which clients have the option to choose any one of a variety of attractive designs that are available

In addition to that, some of the tiles had designs hand-painted onto them, while the rest of the tiles were plain

Glazed Vitrified Tiles Price List

About the glazed vitrified tiles, each company has its own price list according to the manufacturing process

A large number of different substances, including soda, potash, quartz, spherical clay, talc, STPP, and SLS, are included among the raw components that are used in the manufacturing process of slab tiles

The total cost of the digital tile structure is cheaper than that of the entire body glazed tile structure, but the digital tile structure is more costly

Porcelain ceramic tiles

GVT tiles are manufactured using hydraulic presses and have a single layer of GVT

These tiles are known as GVT tiles

After being pushed through the press, the tiles are sent through either a vertical or a horizontal dryer to complete the drying process

The tiles undergo a preliminary roasting procedure in the dryer after being removed from the press and before continuing on to the next step

Printing the tiles requires first applying a variety of surface coatings on them, which is then followed by the printing process

After that, a wide range of distinct designs and patterns are created utilizing inkjet printers of a big size

The CMYK color space is used by many different kinds of digital devices, including those that are brown, yellow, cobalt, or black in hue

The printing machine may contain anywhere from three to 10 print heads, all of which are dependent on the various designs and colors that are to be produced

After that, the tiles are put into an oven at a temperature of around 1200 degrees Celsius, where they are burnt in order to change them into a tile that is resistant to wear and tear and will survive for a very long time

In order to get a shiny and glossy finish on glossy tiles, which needs polishing the surface, polishing machines are used in the production process

When polishing, several different kinds of abrasives are used on the surface of the object

The sizing machine determines the required tile sizes and removes any unnecessary edges at the same time

In addition to that, square-measuring devices are utilized

After the box has been packed and PP corner tape has been put around the box, the production process for tiles is complete and the tiles are ready to be sent

In order to prevent the tile box from being damaged or moving around while being transported, exporters of tiles also use wooden pallet carriers

Glazed Vitrified Tiles 600×600

Glazed tiles have a long lifetime_ whether vitrified or not_ and are available in a number of attractive designs in many sizes like 600×600 mm, making them an excellent investment

This tile is a fantastic option for use in both residential and commercial settings because of its remarkable longevity, low porosity, and resistance to stains

It is also an ideal choice for use in outdoor settings

Glazed tile is an upgrade over traditional ceramic tile in that it has a covering of glass particles that makes it resistant to dust and water

This makes glazed tile an attractive alternative to traditional ceramic tile

This layer is not present in the more traditional ceramic tile

Glazed tiles can be found in a wide variety of different varieties, such as vitrified tiles, polished vitrified tiles, full-bodied vitrified tiles, double-charged vitrified tiles, matte ceramic vitrified tiles or vitrified tiles, which are also known as GVT tiles, and polished porcelain vitrified granites tiles

These glazed tiles come in a broad variety of colors and finishes, and they are easy to clean and maintain

In addition, they have a low cleaning need

Tile comes in a few different varieties, including PGVT tile, often known as tiles or tiles with a polished finish

Glazed Vitrified Tiles 600×1200

Glazed vitrified tiles_ in different sizes like 600×1200 mm_ are popular all around the world these days

The process of clay powder pressing is one of the most cutting-edge technologies, and it is used in the manufacturing of vitrified tiles

This method is considered to be one of the most sophisticated technologies

Because of this method, the tiles may have a solid appearance that is also impermeable, have a fine texture, and even have a dramatic contrast between their colors

The fact that ceramic or glazed tiles typically have a water absorption rate that is lower than ceramic tiles by roughly 0

5 percent is what makes them frost resistant or frost resistant

Ceramic tiles have a water absorption rate that is lower than ceramic tiles

Glazed tiles are produced by depositing a special layer of liquid silica over vitrified tiles

This results in the formation of glazed tiles

The fine or glazed holes on the surface of the tiles are clogged during this procedure, which is the reason why the finished tiles have a texture that is uniformly smooth

Polished glazed tiles are glazed tiles that have had an extra coating of glazed material put to them after the initial application of the glazed material to the glazed tiles

This results in the tiles having a more reflective and glossy appearance

The term “vitrified tiles” may be used to refer to any tile that has been burned at very high temperatures; as a consequence of this process, the tile in question absorbs a far less quantity of water than it would have if it had not been vitrified

The glazed tile in issue is the one that was already attached to it when it was purchased

A glaze that gives the tiles a glossy appearance is applied to them just before they are put through the firing process

This phase takes place before the tiles are subjected to temperatures that are very high

On the other hand, unglazed tiles have the ability to have a glaze applied to them at a later time

Sand and clay are the two primary components that are used in the manufacturing process of ceramic tiles

On the other hand, the surface of the ceramic tile that has been glazed may show evidence of a glaze that has the impression of being liquid

When liquid glazes are applied to vitrified tiles, one is able to change the texture, pattern, and color of the tiles

Additionally, the glazes prevent the tile body from becoming stained

Because of this additional layer, bespoke tile patterns can be incorporated into the designs of the tiles

Because of this, the patterns that are used for floor tiles can be found in a wide variety of colors

This is because the patterns are digitally printed

It is most frequently utilized as floor tiles on the walls of the kitchen and bathroom due to the lively appearance that it provides

This is especially typical in regions of the world that have a climate that is hot and humid

Full Body Vitrified Tiles

Tiles that have a full body vitrified have a color and texture that are uniform over the whole of the tile’s surface

As a result, it is resistant to chipping and scratching, and as a result of this, it is considered to be one of the best tiles available for usage in high-traffic areas because of its resistance to these two types of damage

The glazed component that covers this porcelain tile not only makes it resistant to stains and filth but also makes it much simpler to clean than unglazed tiles

Glazed tile is a colloquial term for any tiles that have been glazed

Glazing is a technique that coats the surface of a tile

One of the procedures needed in carrying out this process is heating the tiles to very high temperatures so that they may be cooked

Glazed tiles are those that have a surface that has been glazed and given a glossy appearance

During the firing process, the tiles get an application of glaze before being exposed to temperatures that are exceedingly high

The term “vitrified” comes from the word “glass,” which refers to the production process of anything that resembles glass or glass itself

The word also refers to the origin of the phrase “vitrified” Tiles are considered to be glazed if the glazing process was used in their production

Wall tiles are what you’ll find when you look under the category of glazed tiles

When compared to other types of flooring, tiles are thought to be less likely to become stained and have a lower propensity to take up water as a moisture source

Tiles that have been glazed typically contain a mixture of clay and silica in their composition

This mixture is used to create a tile that is smooth and crystalline in appearance, and it does not contain any pores

Kajaria Glazed Vitrified Tiles

Glazed vitrified tiles are provided for almost all around the world_ like Kajaria

Glazed vitrified tile that has been manufactured by the use of digital printing technology is referred to as GVT tile

This kind of tile is also known as matte ceramic Victorian glazed tiles or glazed vitrified tile

Tile that is both glazed and glazed is often referred to as GVT tile

Admin Vitrified is a manufacturer of vitrified tiles that gives consumers a wide variety of choices about the colors, patterns, and surface textures of GVT tiles

The term “polished porcelain vitrified tile,” which is more often referred to simply as “polished vitrified tile,” is abbreviated as “PGVT Tile

” These tiles are relatively similar to GVT tiles; however, after the digital printing process, a glaze coating is added to the tiles

This step occurs after the digital printing process

This imparts a glossy quality to the tiles and makes them more visually attractive

We are proud of trying to attain the satisfaction of our valuable customers in recent years

This business is what we enjoy doing in the field of tiles!