porcelain tiles kitchen Buying Guide + Great Price

Porcelain tiles are produced by combining genetic bricks and finely ground sand, which is then pressed and fired at a high temperature

Each design is baked into the body of the tile’s surface to create natural-looking tiles that are easy to clean

This makes porcelain ideal for interiors as well as pool copings and surrounds

Raw Material: The extraction and pre-treatment of raw materials are done at this step before manufacture

The process of making porcelain tiles begins with the transportation of raw materials, the majority of which are found locally

Transport This stage is important for forklift usage inside the production as well as the delivery of raw materials to the plant

Porcelain

Production Slurry preparation: spray drying, pressing for green body, and excess humidity removal are the first steps in this stage

The green body tiles are then burned at a temperature of about 1170 °C with any necessary glazing

The final products are packaged and shipped after quality control

Energy sources used in manufacturing include electricity and natural gas

Transport to the Construction Site: During this stage, porcelain tiles are transported to the building sites

Assembly On the worksite: Tiles are assembled using adhesive mortar and water

The following assumptions were made for a 1 m 2 porcelain flooring: 6 kg mortar and 1

5 L water recycling

Types of porcelain tile

How to transport tiles without breaking them

A whole package: The majority of your clients will probably be homeowners that expect you to offer a full range of safe services from beginning to end

Giving guidance on handling, fragility, and tile specs may be part of this

Think about the services that your clients might want you to offer

These could include everything from levelling floors and plastering walls to finishing the placement of bathrooms and kitchens

You’ll probably advise them to work with other professionals, such as plumbers, builders, painters and decorators, interior designers, and showroom fitters, on some projects

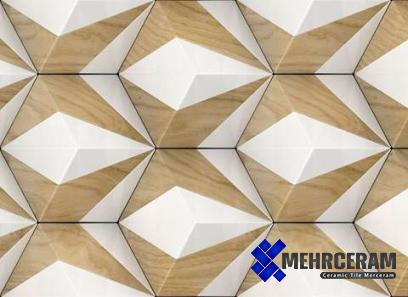

Ceramic tiles floor porcelain polished gloss

How To Place Orders From Us: To order any of our products, please contact our sales team via our Contact page

Your order is an offer to purchase a product or products from us

We reserve the right to refuse any order

If you place an order through our sales line, we will confirm such acceptance to you by sending you written confirmation (usually via email) that your order payment was processed and your order accepted (the “Acceptance of Order”) along with an invoice

Please Note: Tiles Company will not be held responsible for misuse of tile handling that results in unintentional damage to tiles that a client has in their possession after receiving them within the 30-day window

Upon signing for delivery form of the items, risk and ownership are transferred to the consumer

Customers are advised to sign for the delivery as damaged and then notify Ceramic Tiles Company and then agree on a reasonable time frame to report the number of actual tiles damaged from the date of delivery, supported by one photo and, if possible, a brief video

Customers are recommended to order 10% extra to cover cuts, waste, and other issues that may occur

Customers are recommended to add 10% to their orders to cover cuts, waste, and damage that may incur during flooring and during the movement of tiles from the curbside delivery within your property to the area of installation

Please be aware that ordering the precise number of tiles is not necessary to properly execute a tiling project

It is highly recommended that you order 10% extra tiles as regular procedure and save any extras as spares in case of unforeseen circumstances

Porcelain ultra thin tiles

Transporting tiles in Car

Man – made surfaces, including porcelain, seem to require less maintenance than genuine alternatives; for example, rock surfaces require re-sealing every few years to keep them in good shape

Wood floorboards can also be protected with oil and waxing procedures, but you’ll need to replenish them around every six months

Engineered wood with a lacquered finish offers a harder layer of protection on top of the hardwood, but is much more vulnerable to scratch, especially in a room having frequent pedestrian traffic such as the cafeteria

The best way to send tiles is definitely to have them delivered

However, not every stores provide this feature

When purchasing tiles for the first time, you should be aware that they are fragile, weighty, and big

Shipping them is difficult, especially if you are purchasing them from another country

Due to this, the majority of tile shops don’t provide shipment or postage

It’s more difficult than it seems to transfer tiles

It needs unique packing whether by car or other transportation methods

A once-in-a-lifetime opportunity in the transportation sector is to simulate trying to drive a car transporter trailer and carrying enormous amounts of marble tiles

Rocks, roof tiles, as well as other large objects can all be carried by the vehicle trailer that transport trucks are equipped to haul

As long as the right packaging was guaranteed, tiles won’t shatter or crack

What kind of flooring is resistant to scratches? Any floor tile can be scratched or chipped with the proper effort

Unglazed units are less likely to scratch than glazed units, although they aren’t as widely accessible in design options

Pets generally won’t scratch any tiles, although a bit of gravel stuck in a shoe might

How to ship ceramic tiles

Due to their weight and fragility, ceramic tile and glazed brick can be difficult to ship

Given that we ship more than 5000 orders annually, we do our best to box each order properly

Despite this, product breakage and damage do happen infrequently

It’s crucial that you inspect your package as soon as you receive it, noting any outside damage, and record any breakage

Since there is typically at least 10% tile waste from cutting during installations, a little bit of breakage is typically not a big deal

Place any cracked or chipped porcelain tiles aside to be used as cut pieces if you have any

Do not throw them away as-is

Since there is typically at least 10% tile waste from cutting during installations, a little bit of breakage is typically not a big deal

Place any cracked or chipped tiles aside to be used as cut pieces if you have any

They should be kept since they are still useful

You will receive our four-piece sample pack for no cost by USPS in a fitted box with cardboard padding

The elite tiles are carefully wrapped in a larger box with recyclable packaging for larger sample orders

20 square foot and smaller items are shipped by UPS and will arrive double packaged

To make each box lighter, your shipment might be split up into many ones

Upon receiving the shipment, inspect it thoroughly

Orders larger than 20 square feet are transported by truck and delivered on a pallet

As a result of our experience, we are confident that orders as small as three boxes will ship on a pallet for a reasonable price and arrive in better shape

The tile will be boxed up and arranged on a suitable-sized pallet

Compression banding will be used to firmly strap the boxes together

Boxes and tile will be compressed together by this banding, preventing the tile from shattering against one another

Porcelain tiles

For both indoor and exterior use, our company has been producing ceramic and 100% porcelain tiles

Our company’s tiles enhance places with a unique strategy, vibrant colour, effect, and size range, as well as cutting-edge patterns

The business still produces there now

8

5 million square metres worth of production space and 10 million square metres worth of production space

Since its founding, the company has never wavered in its commitment to upholding its reputation for quality and choosing that factor over price as a competitive advantage in order to maximize customer happiness

Due to its use of cutting-edge production techniques, our company enjoys a well-deserved reputation among porcelain producers all over the world

This business, which was Iran’s first technical porcelain factory, is the source of several generic names including Super White, which were developed through an internal R&D and P&D process

It offers 60x60cm and 60x120cm technical porcelain sizes in addition to conventional sizes, and for decades now, it has been the first firm to introduce 90x90cm and 90x135cm tiles to the market

Our production strategy seeks to design national and worldwide initiatives, establish a knowledgeable infrastructure in the sector, foster fresh prospects for collaboration, and produce cutting-edge goods with significant added value

With a wide range of products, we are the go-to brand in projects thanks to our attention-grabbing designs

We express our gratitude to the strong R&D and P&D departments for their ability to quickly respond to requests for product development

The corporate brand manufactures porcelain, pottery, limestone, Persian marble tiles, and many more gizmos

Our company also creates environmentally friendly products within the context of an ecosystem management attitude in accordance with national and international standards in an effort to create a better and cleaner world for future generations

Our nation satisfies all environmental standards as a holder of the Environmental Management System Certificate by utilizing the appropriate raw materials and giving energy efficiency first priority during the production process

Additionally, as part of its environmental protection programme, the company invests in and carries out research projects to utilize its usable waste and wastewater as well as to minimize and improve gas emissions

The goal is to achieve zero waste

Packaging bricks

Tiles and bricks, despite their robustness and rigidity, require the utmost care both during and after the packaging process

This is because there is a high probability that, during transportation, an unstable sea or a rough road can sometimes bring strong wiggle to the vessel and cause compression to the tiles or bricks

Utilization Because porcelain tiles and slabs are made of inert materials, their utilization does not result in the release of any emissions

As a result, the use phase does not play a role in the evaluation

Maintenance is the stage that encompasses all of the operations that are performed during the product’s lifetime in order to ensure that it seems to be doing quite well as intended

Cleaning with water and detergent is included in this step

Porcelain tiles do not require any kind of maintenance or repair while they are in use

Replacement During the use of porcelain tiles, there is no requirement for replacement to take place

Refurbishment: During the use of porcelain tiles, there is no need for any refurbishment to be performed

Utilization of Energy in Operations Porcelain tiles don’t require any additional power to function properly

Deconstruction: The demolition that takes place at the end of RSL is often carried out using a selective deconstruction or demolition strategy

Because of how little of an impact this phase has on the surrounding environment, we may safely ignore them for the time being

The term “Transport (Waste)” refers to the process of transporting unwanted tiles and adhesive mortar to their final disposal location

It is anticipated that there is a distance of fifty kilometers between the site of the demolition and the site of the inert dump where the waste will be disposed of permanently

Processing involves the processing of used porcelain tiles that have been abandoned in order to recycle and/or reuse them

After they have been demolished, porcelain tiles are not subjected to any sort of processing, therefore this stage can be skipped